Built for Demanding Applications

Built for Demanding Applications

Built for Demanding Applications

Reliable, U.S.-made components trusted across automotive, construction, transportation, water systems, industrial equipment, and more.

High-Quality Rubber Components for Critical Environments

We produce custom rubber parts for OEMs, manufacturers, and equipment builders across a wide range of fields.

Manufacturing & Industrial Equipment

Durable parts that support sealing, vibration control, and long-term equipment performance.

Read More

High-strength components built to withstand load cycles, motion, and outdoor exposure across trucks, trailers, and rail.

Read More

Weather-resistant components that support dependable operation in harsh and debris-heavy field conditions.

Read More

Rubber parts used in sealing systems, vibration reduction, and specialty assemblies.

Read More

Durable, clean-contact components suitable for demanding wash-down and heat environments.

Read More

Water Management & Infrastructure Sealing

Rugged gaskets and sealing components that help protect flow, containment, and system uptime.

Read More

What We Do Best

We produce high-volume rubber parts built for consistent performance and durability

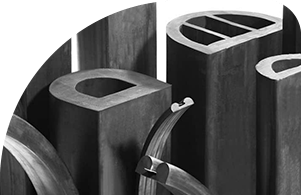

Rubber Extrusion

Continuous profiles built for durability and long-term performance.

View →

Rubber Molding

High-strength molded components made to exact specifications.

View →

Die Cutting

Precise shapes produced from rubber sheets and specialty materials.

View →

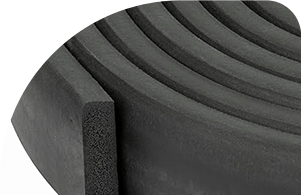

Sponge Extrusion

Flexible profiles used for cushioning, insulation, and sealing applications.

View →

Gold Line Tarp Straps®

Heavy-duty straps trusted for secure load fastening across demanding transport conditions.

View →

Commitment to Quality & Reliability

Quality drives every stage of our workflow. We verify materials, control production conditions, and inspect each run to ensure reliable performance. Our team delivers consistent results, clear communication, and dependable supply for programs of any size.

Blogs

Why EPDM Rubber Remains the Go-To Material for Outdoor Durability

The Advantages of Partnering with a Domestic Rubber Manufacturer

Rubber Tarp Straps Fit to Your Needs

Choosing the Right Seal for Your Commercial Garage Door

What is Automotive NVH?

What Is Rubber Tubing?

What Manufacturers Should Know About Custom Rubber Parts: Rubber Extrusion vs. Die Cut Rubber

Extruded Rubber Profiles for Solar Panel Mounting & Weatherproofing

Properties of Rubber: Heat, Steam & UV Resistance

The Impact of Sri Lanka’s Exports on US Tarp Strap Manufacturers

Proper Application of Tarp Straps

Understanding Rubber Standards for the Automotive Industry

Understanding Extruded Rubber Tolerances

Common Defects in Rubber Extrusion & How to Prevent Them

Exploring UP&R’s Diverse Capabilities

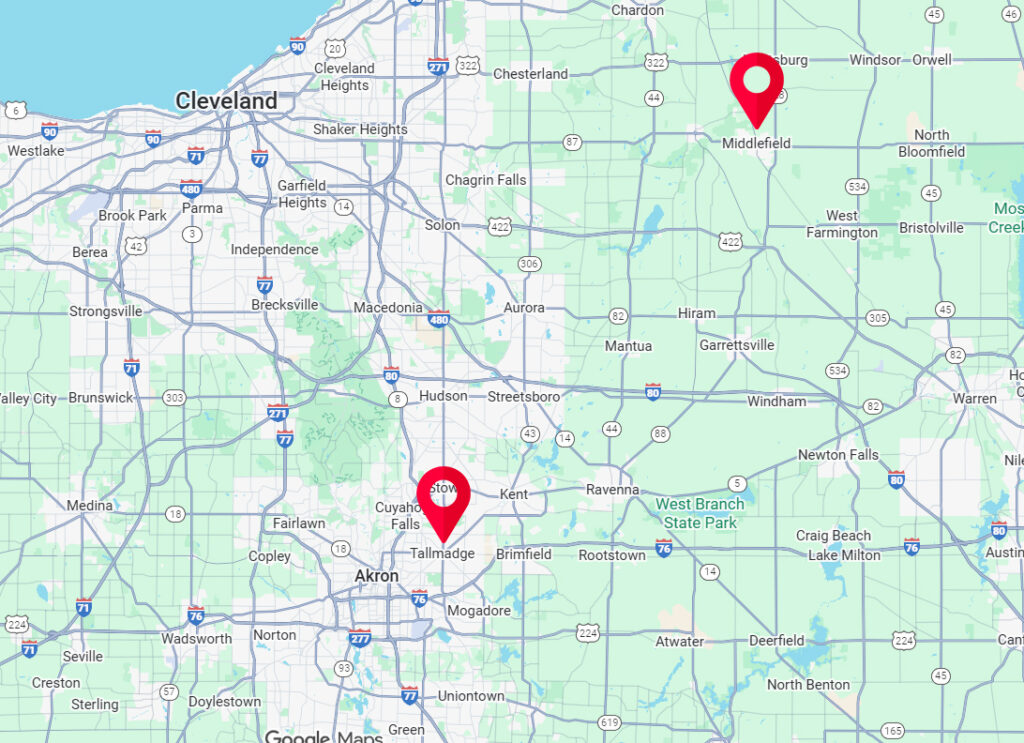

Proudly Manufactured in the USA

A leading site for continuous rubber extrusion and high-accuracy cutting. ISO-9001 certified with decades of production experience supporting diverse applications.

A fast-turn facility specializing in high-mix, high-volume work, molding, extrusion, and follow-up operations. Provides redundancy, added capacity, and stable output across active programs.

Ready to Get Started?

Contact us for guidance, rapid turnaround, and dependable U.S. production.

Contact us for guidance, rapid turnaround, and dependable U.S. production.

About Us

We manufacture custom rubber components using extrusion, molding, and cutting. With more than five decades of U.S. production experience, we provide consistent quality, responsive support, and reliable delivery for companies across a wide range of industries.