At Universal Polymer & Rubber, we are an ISO 9001-certified and IATF-compliant manufacturer of rubber, sponge, and plastic components. Our service offerings include die cutting, which enables us to cut a broad selection of materials into various parts and products. Equipped with custom tooling capabilities, we have what it takes to serve as a single-source vendor for almost any die-cut polymer need, whether the customer is looking for a single component or multiple components.

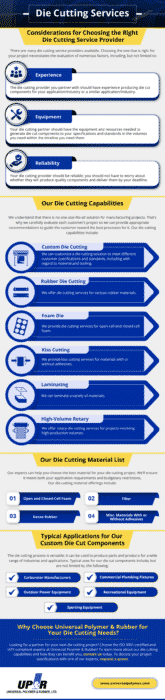

Considerations for Choosing the Right Die Cutting Service Provider

There are many die cutting service providers available. Choosing the one that is right for your project necessitates the evaluation of numerous factors, including, but not

limited to:

- Experience. The die cutting provider you partner with should have experience producing die cut components for your application/industry or a similar application/industry.

- Equipment. Your die cutting partner should have the equipment and resources needed to generate die cut components to your specifications and standards in the volumes you need within the timeline you need them.

- Reliability. Your die cutting provider should be reliable; you should not have to worry about whether they will produce quality components and deliver them by your deadline.

Looking for a reliable die cutting service provider with experience and equipment that match your project needs? We offer a range of non-metallic materials engineered for performance that meets and/or exceeds customer expectations. We can help you choose the one that suits your exact requirements and restrictions and work it to your specifications and standards.

Our Die Cutting Capabilities

We understand that there is no one-size-fits-all solution for manufacturing projects. That’s why we carefully evaluate each customer’s project so we can provide appropriate recommendations to guide the customer toward the best processes for it. Our die cutting capabilities include:

- Custom die cutting. We can customize a die cutting solution to meet different customer specifications and standards, including with regard to material and tooling.

- Rubber die cutting. We offer die cutting services for various rubber materials.

- Foam die cutting. We provide die cutting services for open-cell and closed-cell foam.

- Kiss cutting. We provide kiss cutting services for materials with or without adhesives.

- Laminating. We can laminate a variety of materials.

- High-volume rotary die cutting. We offer rotary die cutting services for projects involving high production volumes.

Our Die Cutting Material List

Our experts can help you choose the best material for your die cutting project. We’ll ensure it meets both your application requirements and budgetary restrictions.

Our die cutting material offerings include:

- Open and closed-cell foam

- Fiber

- Dense rubber

- Misc. materials with or without adhesives

Typical Applications for Our Custom Die Cut Components

The die cutting process is versatile; it can be used to produce parts and products for a wide range of industries and applications. Typical uses for our die cut components include, but are not limited to, the following:

- Carburetor manufacturers

- Commercial plumbing fixtures

- Outdoor power equipment

- Recreational equipment

- Sporting equipment

Why Choose Universal Polymer & Rubber for Your Die Cutting Needs?

Looking for a partner for your next die cutting project? Choose the ISO 9001-certified and IATF-compliant experts at Universal Polymer & Rubber! We can produce die cut components for many different applications, including professional, commercial, and recreational. Additionally, our experience enables us to handle a variety of parts and product needs, which helps customers reduce the number of vendors they have to work with. That’s why some of the top companies in the industry rely on us for die cutting services.

To learn more about our die cutting capabilities and how they can benefit you, contact us today. To discuss your project specifications with one of our experts, request a quote.