Extruded rubber products are lightweight, flexible, extremely durable and long-lasting. Extruded rubber parts are ideal for use in myriad harsh or extreme conditions, such as high temperature environments or applications with significant chemical exposure. The continuous rubber extrusion process can produce parts in a variety of lengths and shapes relatively cost-effectively and with very little material waste.

Universal Polymer & Rubber (UP&R) solves challenges for our extrusion customers from part development and manufacture, to polymer selection, through meeting end customer requirements.

Rubber Extrusion: How it Works

Rubber extrusion is a process used to manufacture rubber products. The process uses an extrusion machine to force synthetic or natural rubber material through a shaped die under high pressure. The material used is typically soft, un-vulcanized rubber. The process shapes the workpiece in a soft, pliable state, after which it is vulcanized to harden the workpiece into a usable final product.

A rubber extruder machine is composed of two primary parts. A heated shearing screw pushes the raw material along a conveyor as compounds are fed into the extruder. As the material moves along the conveyor, it is heated and softened to make it pliable. The softened material is pressurized by the shearing screw and forced into the die where it takes its final shape.

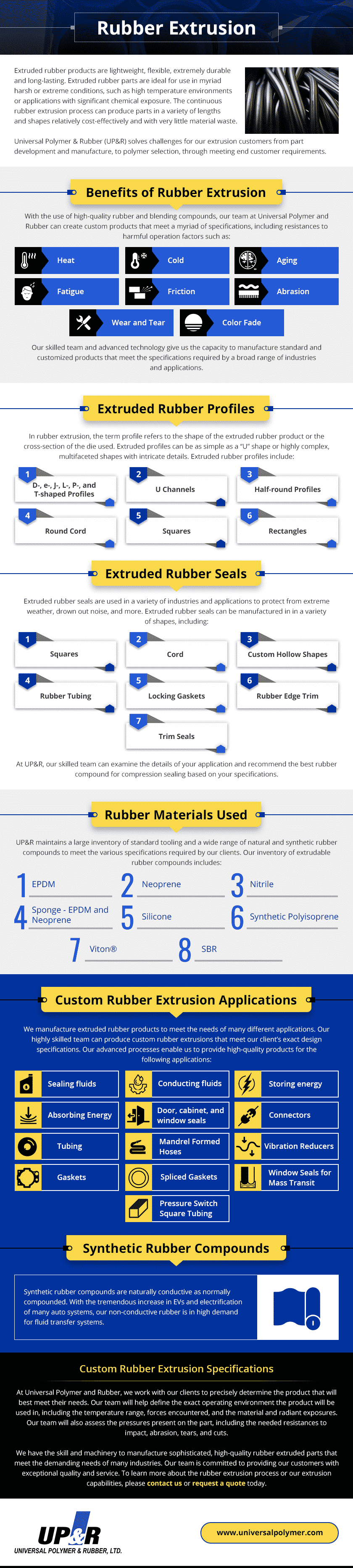

Benefits of Rubber Extrusion

Rubber extrusion is an efficient and economical manufacturing process. The volume of wasted material in the extrusion process is minimal, and the production costs are typically lower when compared to other production methods. Rubber extrusion is a continuous process that can produce finished products of different lengths in a variety of shapes.

With the use of high-quality rubber and blending compounds, our team at Universal Polymer and Rubber can create custom products that meet a myriad of specifications, including resistances to harmful operation factors such as:

- Heat

- Cold

- Aging

- Fatigue

- Friction

- Abrasion

- Wear and tear

- Color fade

Our skilled team and advanced technology give us the capacity to manufacture standard and customized products that meet the specifications required by a broad range of industries and applications.

Extruded Rubber Profiles

In rubber extrusion, the term profile refers to the shape of the extruded rubber product or the cross-section of the die used. Extruded profiles can be as simple as a “U” shape or highly complex, multifaceted shapes with intricate details. Extruded rubber profiles include:

- D-, e-, J-, L-, P-, and T-shaped profiles

- U channels

- Half-round profiles

- Round cord

- Squares

- Rectangles

Extruded Rubber Seals

Extruded rubber seals are used in a variety of industries and applications to protect from extreme weather, drown out noise, and more. Extruded rubber seals can be manufactured in in a variety of shapes, including:

- Squares

- Cord

- Custom hollow shapes

- Rubber tubing

- Locking gaskets

- Rubber edge trim

- Trim seals

At UP&R, our skilled team can examine the details of your application and recommend the best rubber compound for compression sealing based on your specifications.

Rubber Materials Used

UP&R maintains a large inventory of standard tooling and a wide range of natural and synthetic rubber compounds to meet the various specifications required by our clients. Our inventory of extrudable rubber compounds includes:

- EPDM

- Neoprene

- Nitrile SBR

- Sponge EPDM and Neoprene

- Silicone

- Synthetic polyisoprene

- Viton®

Custom Rubber Extrusion Applications

We manufacture extruded rubber products to meet the needs of many different applications. Our highly skilled team can produce custom rubber extrusions that meet our client’s exact design specifications. Our advanced processes enable us to provide high-quality products for the following applications:

- Concrete pipe and manhole gaskets

- Plastic pipe gaskets

- Cast iron coupling gaskets

- Sealing fluids

- Conducting fluids

- Storing energy

- Absorbing energy

- Door, cabinet, and window seals

- Connectors

- Tubing

- Mandrel formed hoses

- Vibration reducers

- Gaskets

- Spliced gaskets

- Window seals for mass transit

- Pressure switch square tubing

Custom Rubber Extrusion Specifications

At Universal Polymer and Rubber, we work with our clients to precisely determine the product that will best meet their needs. Our team will help define the exact operating environment the product will be used in, including the temperature range, forces encountered, and the material and radiant exposures. Our team will also assess the pressures present on the part, including the needed resistances to impact, abrasion, tears, and cuts.

We have the skill and machinery to manufacture sophisticated, high-quality rubber extruded parts that meet the demanding needs of many industries. Our team is committed to providing our customers with exceptional quality and service. To learn more about the rubber extrusion process or our extrusion capabilities, please contact us or request a quote today.