Products made from rubber begin with uncured natural rubber or synthetic elastomer, which undergoes a comprehensive curing and vulcanizing process to toughen the material. Determining the most appropriate rubber molding methodology largely depends on budget restraints, available equipment, and tolerance requirements for the final rubber part. When using any type of rubber molding method, such as injection, compression, and transfer molding, deflashing must also occur.

Deflashing is the removal of any waste—or “flash”—created during the rubber molding production procedure using manual tear trimming, tumbling, cryogenic processing, or precision grinding.

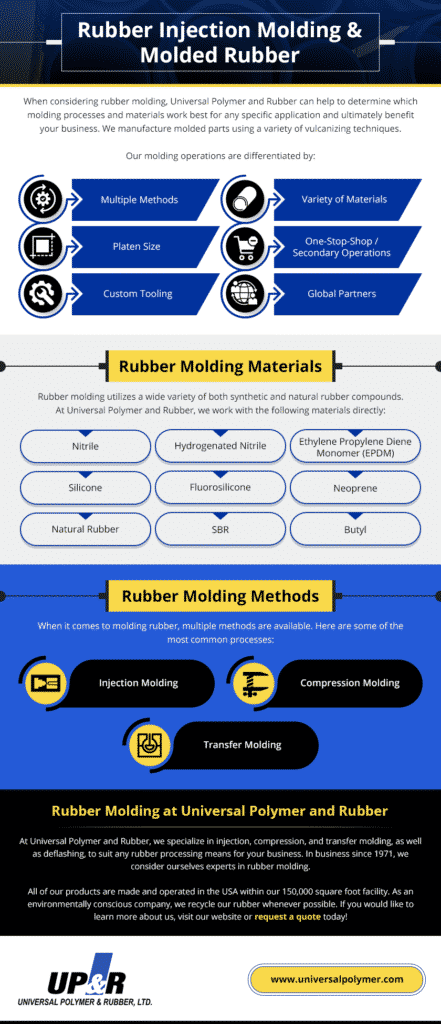

When considering rubber molding, Universal Polymer and Rubber can help to determine which molding processes and materials work best for any specific application and ultimately benefit your business.

We manufacture molded parts using a variety of vulcanizing techniques.

- Our molding operations are differentiated by:

- Multiple Methods. Injection, compression, and transfer presses

- Variety of Materials. Viton/FKM, silicone, neoprene, nitrile, EPDM, SBR

- Platen Size. Up to 36” wide x 36” long

- One-Stop-Shop / Secondary Operations. Hole punching, drilling, printing, taping, and assembly

- Custom Tooling. UP&R works hand-in-hand with trusted local tool makers to develop parts from customer-supplied designs

- Global Partners. UP&R has developed a network of international molding partners to enable total value satisfaction for the customer

Rubber Molding Materials

Rubber molding utilizes a wide variety of both synthetic and natural rubber compounds. At Universal Polymer and Rubber, we work with the following materials directly:

- Nitrile. With robust mechanical properties, nitrile offers an ideal solution for many applications. This material is primarily selected for its superior resistance to oils.

- Hydrogenated Nitrile. More expensive than standard nitrile, this compound is a hydrogenated variation of nitrile. It offers increased resistance to heat, petroleum, and an almost five-fold increase in ozone resistance. Frequently found in automotive, aircraft and marine industries, this material sees primary use for seals, engine parts, fuel systems, among others.

- Ethylene Propylene Diene Monomer (EPDM). With a wide temperature range and high resistance to brake fluids, EPDM commonly sees use in steam systems, brake systems, vehicle seals. EPDM is the most popular and cost-effective synthetic rubber polymer.

- Silicone. This flexible material has high and low-temperature resistance, as well as strong weather resistance. Though regularly found in medical equipment and food processing, silicone tears easily, so it does not serve as a good option for high-wear scenarios.

- Fluorosilicone. Offering the same temperature range as silicone combined with the added resistance to oils, fuels, and fluorocarbon solvents, this material works well in aerospace applications. Weak abrasion and friction resistance may make it poor for abrasive scenarios, however.

- Neoprene. A large number of molding solutions makes this fire-resistant material a smart choice. With strong abrasion properties, it can be found in mass-transit and transportation equipment such as motor components, shock absorbers, vibration mountings, and seals, among others.

- Natural Rubber. Produced from latex derived from a rubber tree, natural rubber has high tensile strength, surface strength, and abrasion resistance. Ideal for seals, vibration-dampers, O-rings, mountings, and bumpers, this material also bonds well with metal. However, with low tolerance to UV rays and ozone, it should not be exposed to petroleum-based products or sunlight.

- SBR. As a cost-effective polymer often found in tires, seals, gaskets, diaphragms, and other mass-produced rubber products, styrene butadiene has excellent durability. Though an excellent material for water-based applications, this material may not prove suitable for prolonged exposure to petroleum products or solvents.

- Butyl. With low gas and moisture permeability and strong sound dampening qualities, butyl serves as an ideal and cost-effective material for vacuums and high-pressure gas systems. However, if products will see exposure to petroleum or abrasion, this material should not be used.

Rubber Molding Methods

When it comes to molding rubber, multiple methods are available. Here are some of the most common processes:

- Injection molding. In rubber injection molding, a heating procedure enables the flow of an uncured rubber compound. Then, the liquified rubber injects into the mold, where it hardens.

- Compression molding. With compression molding, manufacturers place a rubber compound into a mold cavity, enclose both sides, and add heat during the pressurizing process.

- Transfer molding. Transfer molding can also serve as an appropriate means for molding rubber. This type of process also relies on pressure. During the transfer molding procedure, a plunger forces the rubber compound into a mold where the rubber takes its final form.

Though all of these methods may be available as options for a rubber molding project, Universal Polymer can help identify the right molding process for the materials and designs involved in a specific project. Additionally, our deflashing operations ensure the removal of “flash” or waste after any of these methods of rubber molding.

Rubber Molding at Universal Polymer and Rubber

At Universal Polymer and Rubber, we specialize in injection, compression, and transfer molding, as well as deflashing, to suit any rubber processing means for your business. In business since 1971, we consider ourselves experts in rubber molding.

All of our products are made and operated in the USA within our 150,000 square foot facility. As an environmentally conscious company, we recycle our rubber whenever possible. If you would like to learn more about us, visit our website or request a quote today!