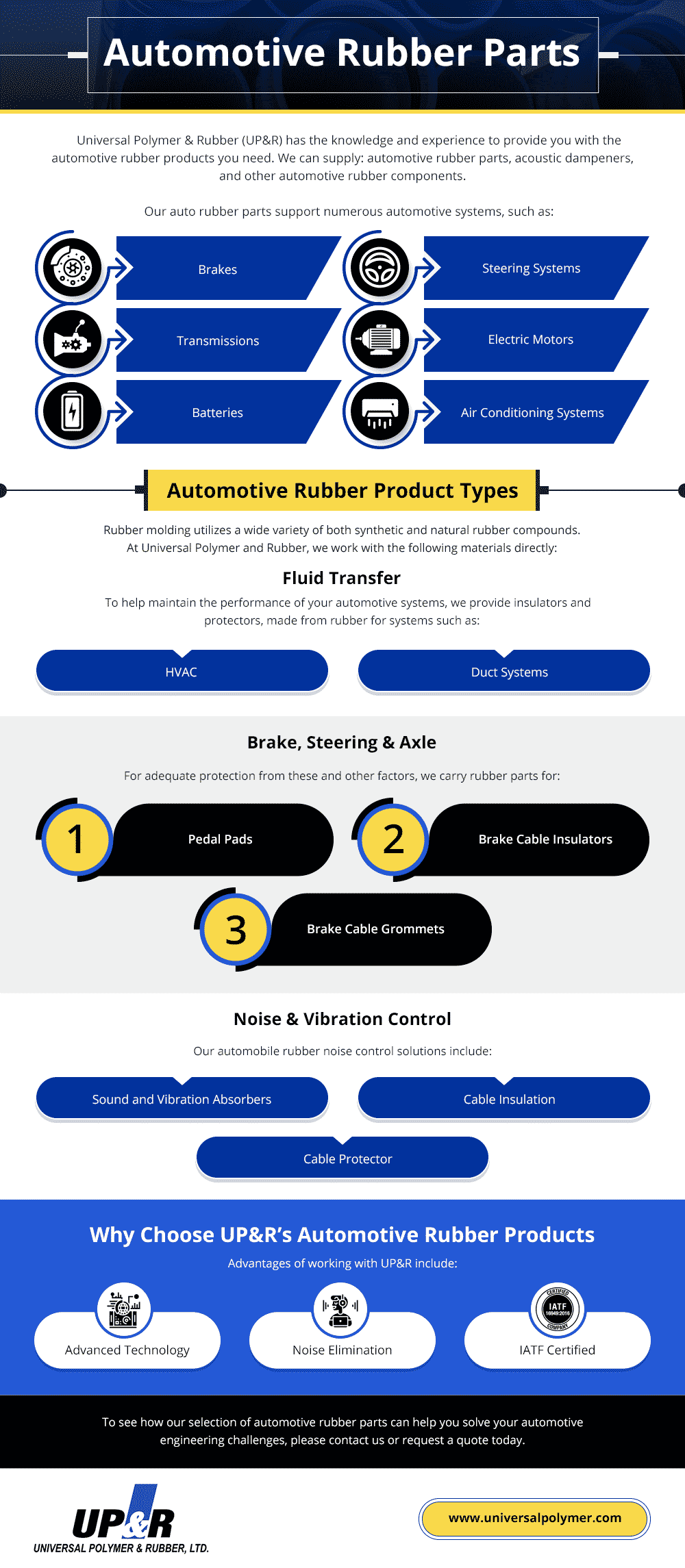

Universal Polymer & Rubber (UP&R) has the knowledge and experience to provide you with the automotive rubber products you need. We can supply automotive rubber parts, acoustic dampeners, and other automotive rubber components. Our auto rubber parts support numerous automotive systems, such as brakes, steering systems, transmissions, electric motors, batteries, air conditioning systems, and more.

We follow strict quality assurance measures to ensure we only deliver top-quality products. To this end, both of our USA factories are certified to IATF-16949.

Automotive Rubber Product Types

Depending on your application’s needs, we can provide a compatible automotive rubber part. Our selection includes rubber car parts for the following:

Fluid Transfer

Systems that transfer fuel, coolant, and other fluids require high-quality rubber to prevent wear and corrosion over time. Rubber parts hold up in harsh engine environments and assist in compliance with emissions regulations. To help maintain the performance of your automotive systems, we provide insulators and protectors, made from rubber for systems such as:

- HVAC

- Duct systems

Brake, Steering & Axle

Components of braking, steering, and axle systems require materials that can withstand extreme operating temperatures and frictional heat. For adequate protection from these and other factors, we carry rubber parts for:

- Pedal pads

- Brake cable insulators

- Brake cable grommets

Noise & Vibration Control

Noise-eliminating components help to avoid troublesome noises caused by vibrating and rattling parts. Incorporating rubber can help remove unwanted noise in a vehicle. Our automobile rubber noise control solutions include:

- Sound and vibration absorbers

- Cable insulation

- Cable protector

Why Choose UP&R’s Automotive Rubber Products

Universal Polymer & Rubber is a premier automotive gasket manufacturer and supplier of automotive rubber parts. We were among the early adopters of non-conductive rubber now used in many modern vehicles, demonstrating our commitment to developing innovative solutions for our customers. The advantages of working with UP&R include:

Advanced Technology

Today’s automotive designs rely on more electronics as they transition from traditional mechanical components to digital solutions. One of the most significant innovations in the industry has been the increased adoption of electric vehicles (EVs), which has led to the increased demand for non-conductive rubber to insulate wiring and cables. This demand is in addition to the non-conductive rubber already used to insulate and protect electrical components in internal combustion vehicles.

Non-conductive rubber offers a cost-effective solution for manufacturers because it resists breakage and provides valuable protection for other critical system components. Numerous vehicle parts rely on non-conductive rubber for insulation, from heated seats and digital display screens to automated windows and mirrors.

Noise Elimination

Squeaks and rattles commonly plague automotive engineers, and designers search extensively for solutions to eliminate these problems. Our rubber products prevent unwanted noise from fluid transfer components and other vehicle systems.

IATF Certified

Any business working with the automotive sector should demand IATF certification to guarantee product quality. Currently, only a small percentage of manufacturing companies worldwide are IATF-certified, as it’s one of the most challenging to obtain. Every part produced at UP&R meets IATF 16949 industry standards for defect prevention, continued improvement, and waste minimization along the supply chain.

To see how our selection of automotive rubber parts can help you solve your automotive engineering challenges, please contact us or request a quote today.